- Barbed Wire[10]

- Steel Wire Mesh[10]

- Other Wire Mesh[10]

- Other Animal Husbandry Equipment[1]

- Stainless Steel Wire[7]

- Plastic Nets[10]

- Iron Wire Mesh[10]

- Metal Building Materials[3]

- Filter Meshes[6]

- Steel Sheets[3]

- Traffic Barrier[1]

- Fencing[4]

- Rubber Hoses[1]

- Plumbing Hoses[5]

- Storage Baskets[1]

- Fiberglass Mesh[5]

- Other Non-Metallic Minerals & Products[1]

- Iron Wire[8]

- Contact Person : Mr. Sun Shengbin

- Company Name : Anping Xiangyu Metal Wire Mesh Co., Ltd.

- Tel : 86-318-7632002,7635799,7632900

- Fax : 86-318-7633788

- Address : Hebei,Anping,wire mesh world industrial park anping hebei,china

- Country/Region : China

- Zip : 053600

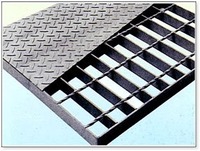

offer plain steel grating

STEEL GARTING

1> Bearing bar pitches may be 15 to 22, 25, 30, 32.5, 34, 40, 50, 60, 80, 90mm, of which 25,

30, 34 and 40mm are recommended.2> Cross bar pitches maybe 24-200mm, of which 50mm, 76mm and 100mm are recommended.3> Steel grating is made by the world first-class equipment, which can arrange the bearing bar and cross bar in longitude and latitude

order to certain distance. Cross bar is pressed into the bearing bar by high tension resistance

weldingring which is controlled by computer. So we can produce high quality gratings with firm

welding, smooth surface and high strength.4> Surface Process of Gratings: there are three types: hot-dipped galvanizing , Elec-Galvanized andSpraying brushing and soaking. Anti-acid and alkali corrosion capacity: the range PH6 to PH12.5, a stable protective film will be

formed on the zinc surface. It has good anti-corrosive property.5. >Packing Conditions of Steel Grating: Normally packed in piling up ways with two

pieces of square wood on both upper and bottom sides. There are four or six pieces of M10

long bolt penetrating the gratings and screwing together. It is suitable for loading and

unloading by fork-lift and crane. Note: we can pack as per the requirement of customers.6 >Installation of steel Grating:A) There are two ways of installation for grating. One way is by welding and the other is by

installation fastenter. The welding method is suitable for those parts which will be fixed forever,

such as platforms for equipments, while the method by installation fastener has the properties

of easy to assemble and disassemble and of preventing destroying the zinc layer.B) Installation fastener is suitable for all types of gratings. It is made of up fastener, down-fastenet and inside turret cylinder bolt M10.C) Welding method is angle welding at the first bearing bar of every corners on the grating.

wear resistance

SKYPE:anna20102112;msn:xywiremesh;alitalk:cgs_yishung.

Welcome to visit and order my products.

offer plain steel grating